Introduction Of Steel Grating

Steel grating, with robust design and spanning abilities, is very strong and safe for the support of floors and elevated walkway. It can be used for ceiling, interior decoration, platform aisle, ventilation windows, (Wells), advertising plaque and other construction.

Features Of Galvanized Steel Grating

High strength: Due to its structural characteristics, steel grating has a high load-bearing capacity.

Lightweight: Compared to other materials with the same load-bearing capacity, steel grating is lighter and easier to transport and install.

Durability: After appropriate surface treatment, steel grating can resist corrosion and extend its service life.

Ventilation and light transmission: Due to its grid like structure, steel grating has good ventilation and light transmission performance.

Anti slip: The surface can be treated with anti slip measures to increase safety.

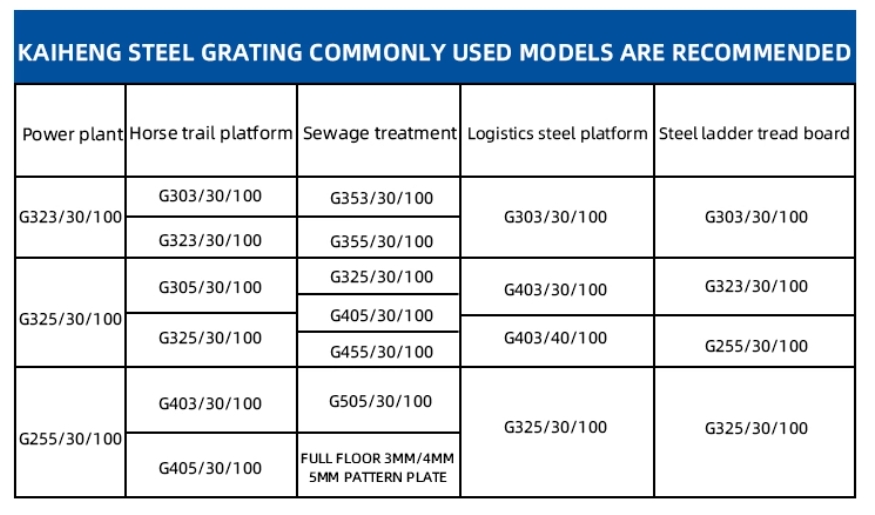

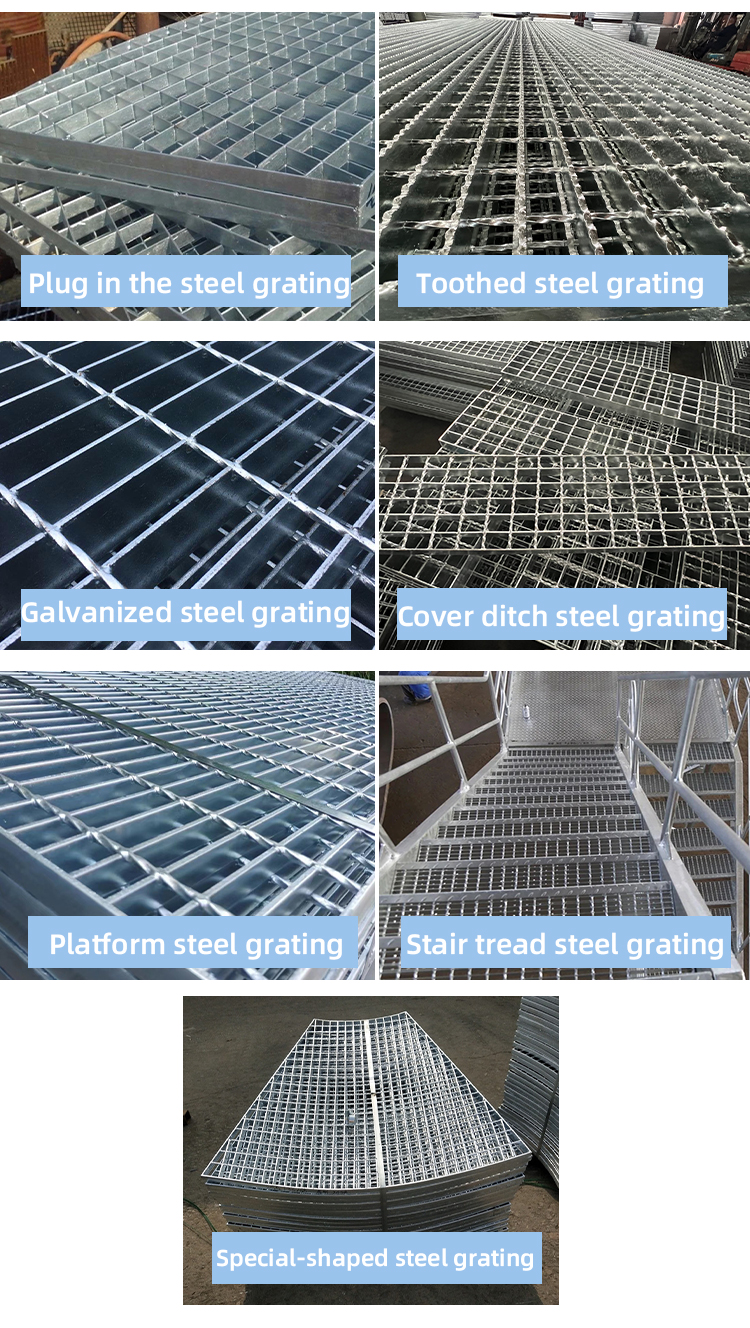

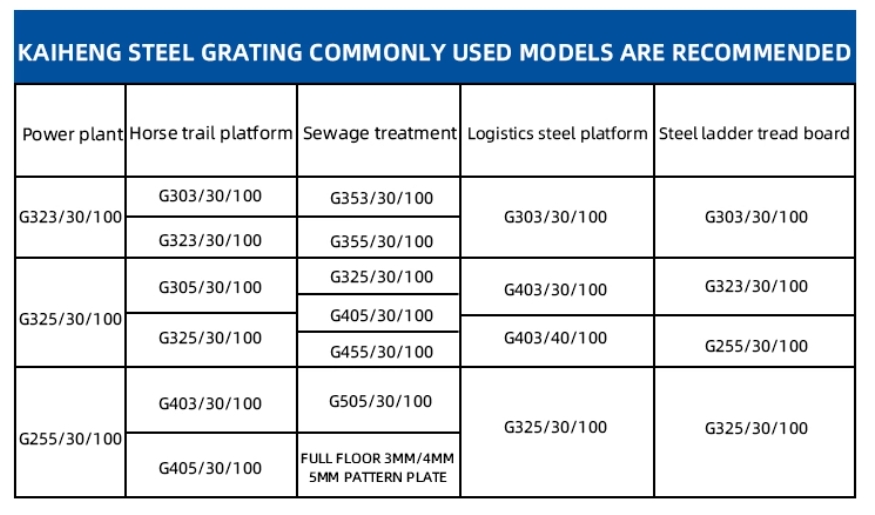

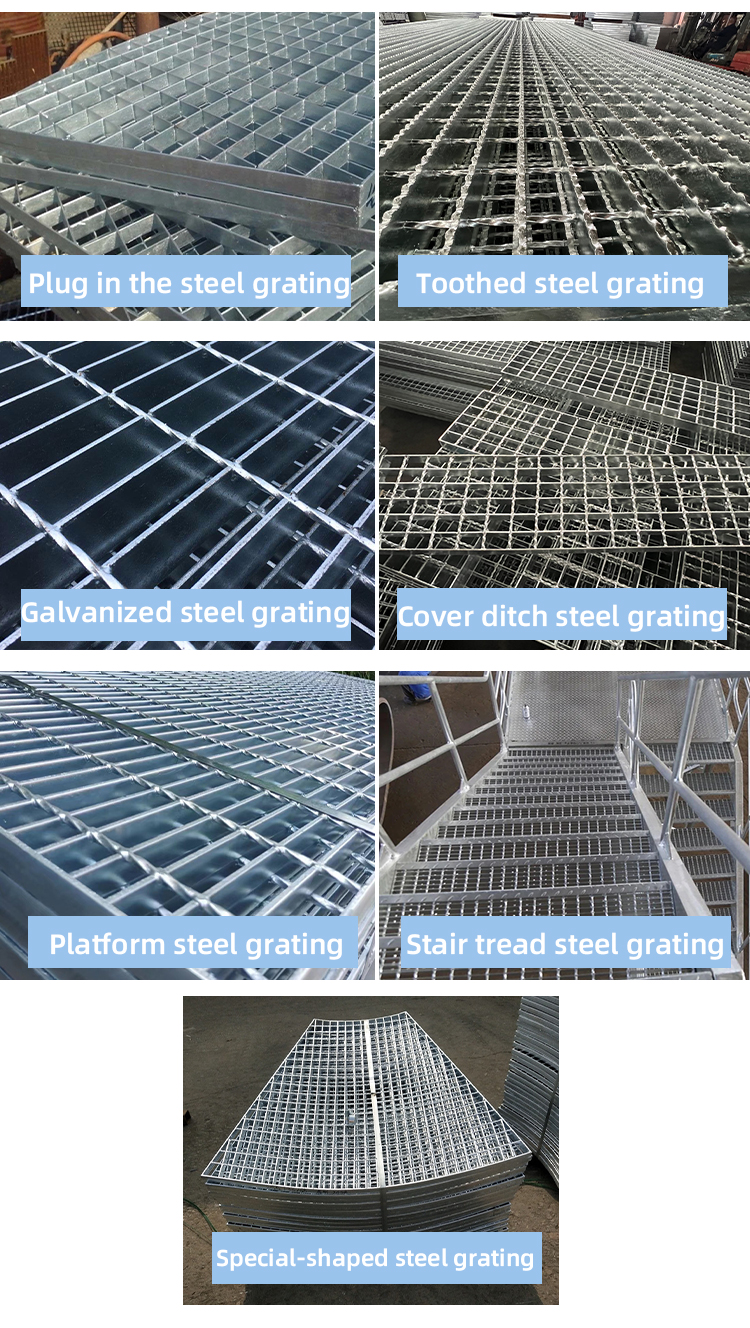

Kinds Of Steel Grating

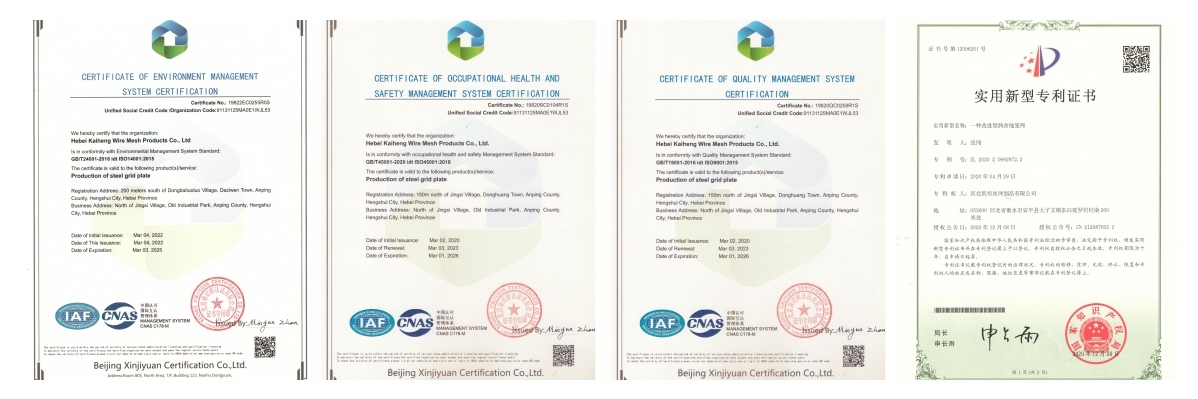

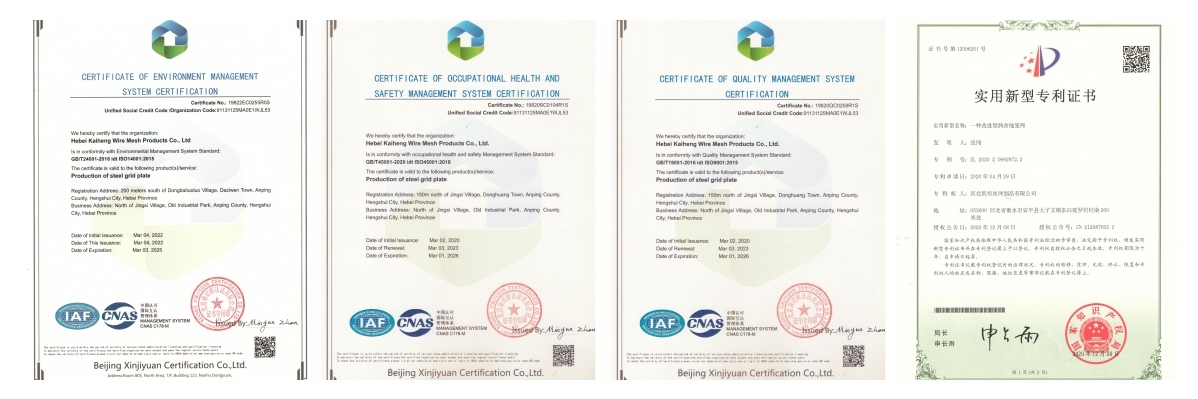

OUR CERTIFICATE

Our Factory Production

Hebei Kaiheng Wire Mesh Products Co. Ltd. is a leading manufacturer of steel grating platesproducing over 3000 plates daily and holding multiple quality certifications, focusing on industriessuch as petrochemical and hydropower.

With a high-end intelligent industrial park integrating production and research and developmentand two patent information items, Kaiheng specializes in the steel grating series and offerscustomized solutions tailored to meet the needs of various customers.

Our Packaging And Transportation

1. International standard logistics packaging and transportation.

2. If customers have needs, we can customize special LOGO

3. Shanghai, Tianjin, Qingdao, Ningbo ports, you can specify other ports according to your needs.

Our After-sale Service

Provide a one-year product warranty to protect customer interests and ensure their peace of mind during use.

Sample service:

Simplify the process for customers to request samples, and customers only need to pay for shipping to personally evaluate product quality.

Customized services:

We specialize in providing customized services, making products based on the drawings and specifications provided by customers to meet their specific needs.

Quality assurance:

Provide pre production samples before mass production to ensure that the product meets customer expectations, and conduct a comprehensive inspection before shipment to ensure quality.

Global coverage:

Having a strong global sales network, able to quickly respond and meet the diverse needs of customers in different geographical locations.

ABOUT US

We are China sheet metal fabricator specializing in laser cutting, CNC bending, welding, polishing,powder coating and assembling with 20+ years custom- made sheet metal fabricationexperience, support OEM/ ODM, provide one- stop custom sheet metal fabrication services

We serve on demand sheet metal fabrication and technical support for wide ranges of industries.

More than 2000 customers from all around world receive flexible manufacturing support and getthe most cost effective custom metal parts solutions.