| Availability: | |

|---|---|

| Quantity: | |

| Parameter | Value |

|---|---|

| Product Name | Stainless Steel Weld Bar Platform Steel Grating for Drainage Stairs Security Fence |

| Origin | Hebei, China |

| Warranty | 1 year |

| Chemical Composition | C, Mn, P, S, etc |

| Alloy Type | Non-Alloy |

| Brand | Kaiheng |

| Model | Customized |

| Shape | Serrated, Plain, I bar grating |

| Size | Customized Size |

| Material | Steel |

| Surface Treatment | Hot-dipped galvanized, Painted |

| Application | Platforms, stairs, Drainage ditch, and protective fence |

| Type | Pressure welded, pressure locked, socket welding |

| Color | Any color available |

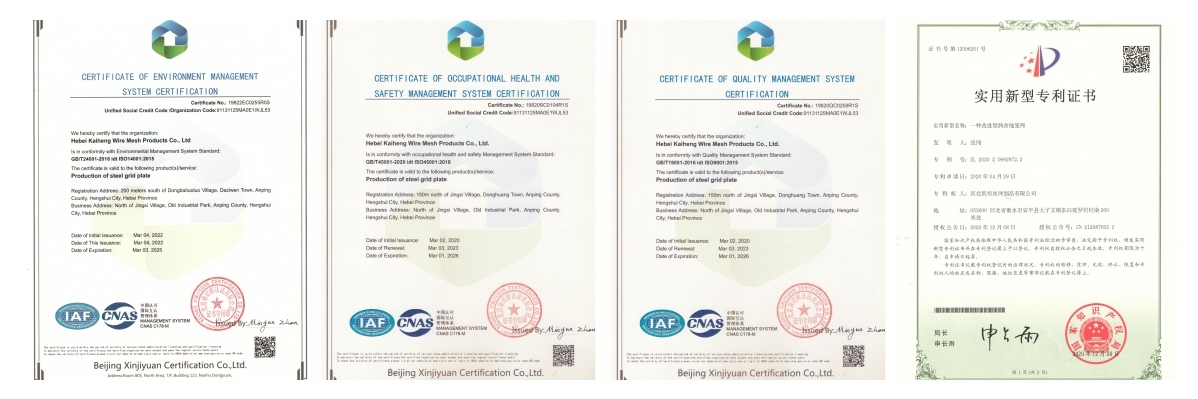

| Certification | ISO9001 |

| Surface Finish | Smooth, Matte |

| Processing Services | Cutting, Punching |

| Moq | 1 ton |

| Service Life | 20+ years |

| Payment Methods | T/T, L/C, PayPal, etc |

| Delivery | Quick delivery, standard exporting package |

| OEM/ODM | Available |

Hot-dip galvanized steel grating, made from mild carbon steel, is engineered with a robust design and exceptional spanning capabilities. It offers remarkable strength and safety, making it ideal for supporting floors and elevated walkways. This type of grating features superior drainage performance, with a leakage area of 83.3%, which is more than double that of cast iron products.

Steel gratings are specifically designed and manufactured to meet the diverse needs of various industrial and civil construction projects, including city roads, gardens, yards, airports, railways, and industrial engineering applications.

Flexible Application: Suitable for a wide range of applications including platforms, stairs, drainage ditches, and security fences, providing versatility in industrial and civil construction projects.

Enhanced Safety: Serrated edges provide better traction, reducing the risk of slipping on elevated walkways and stairs.

Ease of Installation: Available in various types of connections such as pressure welded, pressure locked, and socket welding, making it easy to install in different environments.

Environmentally Friendly: The grating is designed to be eco-friendly with materials that are recyclable, supporting sustainable construction practices.

Long-Term Performance: The steel grating is engineered to withstand harsh conditions, ensuring reliable performance in both high-traffic and extreme weather areas.

With over 20 years of expertise in custom sheet metal fabrication, we specialize in laser cutting, CNC bending, welding, polishing, powder coating, and assembly. Our comprehensive one-stop services are tailored to meet the unique needs of each client, offering both OEM and ODM solutions.

We provide flexible, on-demand sheet metal fabrication and technical support across various industries. Our global clientele of over 2000 customers benefits from cost-effective, high-quality custom metal parts that are designed to meet their specific requirements.

By leveraging advanced technologies and a customer-centric approach, we deliver efficient, reliable solutions that help businesses thrive in competitive markets.

Hebei Kaiheng Wire Mesh Products Co. Ltd. is a leading manufacturer of steel grating platesproducing over 3000 plates daily and holding multiple quality certifications, focusing on industriessuch as petrochemical and hydropower.

With a high-end intelligent industrial park integrating production and research and developmentand two patent information items, Kaiheng specializes in the steel grating series and offerscustomized solutions tailored to meet the needs of various customers.

| Parameter | Value |

|---|---|

| Product Name | Stainless Steel Weld Bar Platform Steel Grating for Drainage Stairs Security Fence |

| Origin | Hebei, China |

| Warranty | 1 year |

| Chemical Composition | C, Mn, P, S, etc |

| Alloy Type | Non-Alloy |

| Brand | Kaiheng |

| Model | Customized |

| Shape | Serrated, Plain, I bar grating |

| Size | Customized Size |

| Material | Steel |

| Surface Treatment | Hot-dipped galvanized, Painted |

| Application | Platforms, stairs, Drainage ditch, and protective fence |

| Type | Pressure welded, pressure locked, socket welding |

| Color | Any color available |

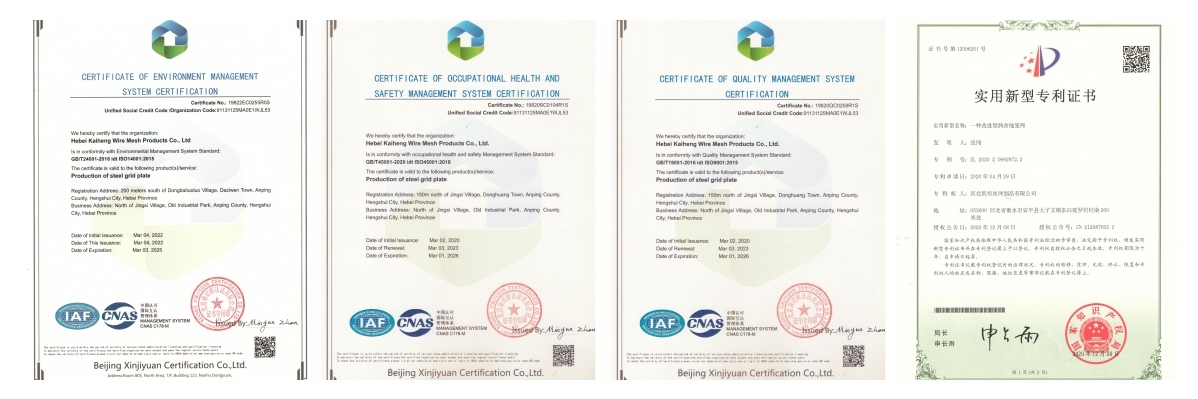

| Certification | ISO9001 |

| Surface Finish | Smooth, Matte |

| Processing Services | Cutting, Punching |

| Moq | 1 ton |

| Service Life | 20+ years |

| Payment Methods | T/T, L/C, PayPal, etc |

| Delivery | Quick delivery, standard exporting package |

| OEM/ODM | Available |

Hot-dip galvanized steel grating, made from mild carbon steel, is engineered with a robust design and exceptional spanning capabilities. It offers remarkable strength and safety, making it ideal for supporting floors and elevated walkways. This type of grating features superior drainage performance, with a leakage area of 83.3%, which is more than double that of cast iron products.

Steel gratings are specifically designed and manufactured to meet the diverse needs of various industrial and civil construction projects, including city roads, gardens, yards, airports, railways, and industrial engineering applications.

Flexible Application: Suitable for a wide range of applications including platforms, stairs, drainage ditches, and security fences, providing versatility in industrial and civil construction projects.

Enhanced Safety: Serrated edges provide better traction, reducing the risk of slipping on elevated walkways and stairs.

Ease of Installation: Available in various types of connections such as pressure welded, pressure locked, and socket welding, making it easy to install in different environments.

Environmentally Friendly: The grating is designed to be eco-friendly with materials that are recyclable, supporting sustainable construction practices.

Long-Term Performance: The steel grating is engineered to withstand harsh conditions, ensuring reliable performance in both high-traffic and extreme weather areas.

With over 20 years of expertise in custom sheet metal fabrication, we specialize in laser cutting, CNC bending, welding, polishing, powder coating, and assembly. Our comprehensive one-stop services are tailored to meet the unique needs of each client, offering both OEM and ODM solutions.

We provide flexible, on-demand sheet metal fabrication and technical support across various industries. Our global clientele of over 2000 customers benefits from cost-effective, high-quality custom metal parts that are designed to meet their specific requirements.

By leveraging advanced technologies and a customer-centric approach, we deliver efficient, reliable solutions that help businesses thrive in competitive markets.

Hebei Kaiheng Wire Mesh Products Co. Ltd. is a leading manufacturer of steel grating platesproducing over 3000 plates daily and holding multiple quality certifications, focusing on industriessuch as petrochemical and hydropower.

With a high-end intelligent industrial park integrating production and research and developmentand two patent information items, Kaiheng specializes in the steel grating series and offerscustomized solutions tailored to meet the needs of various customers.