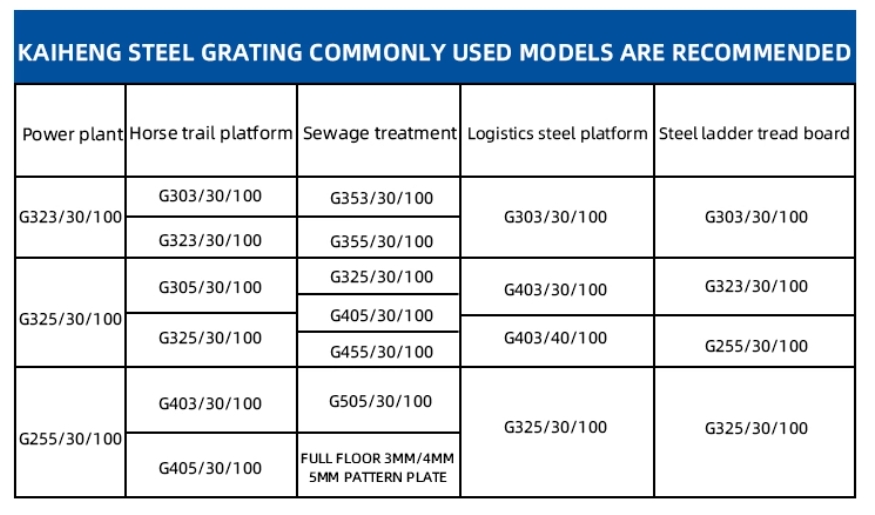

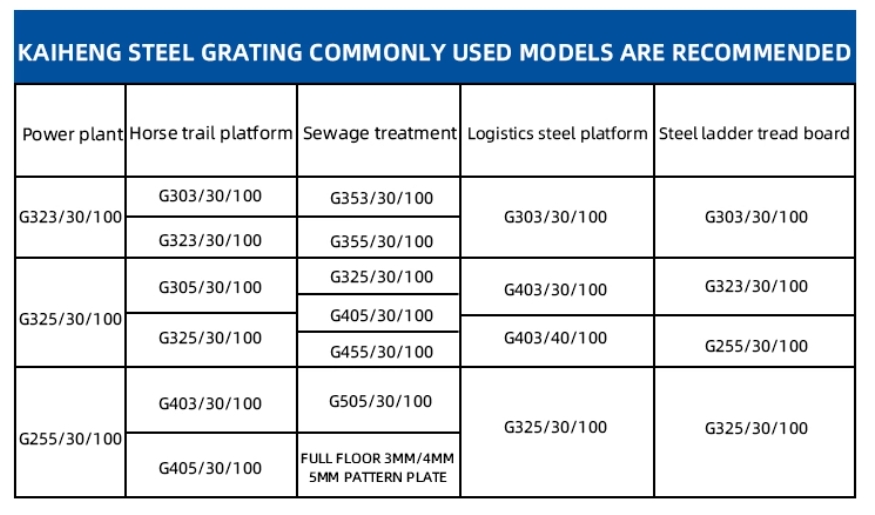

Introduction Of Steel Grating

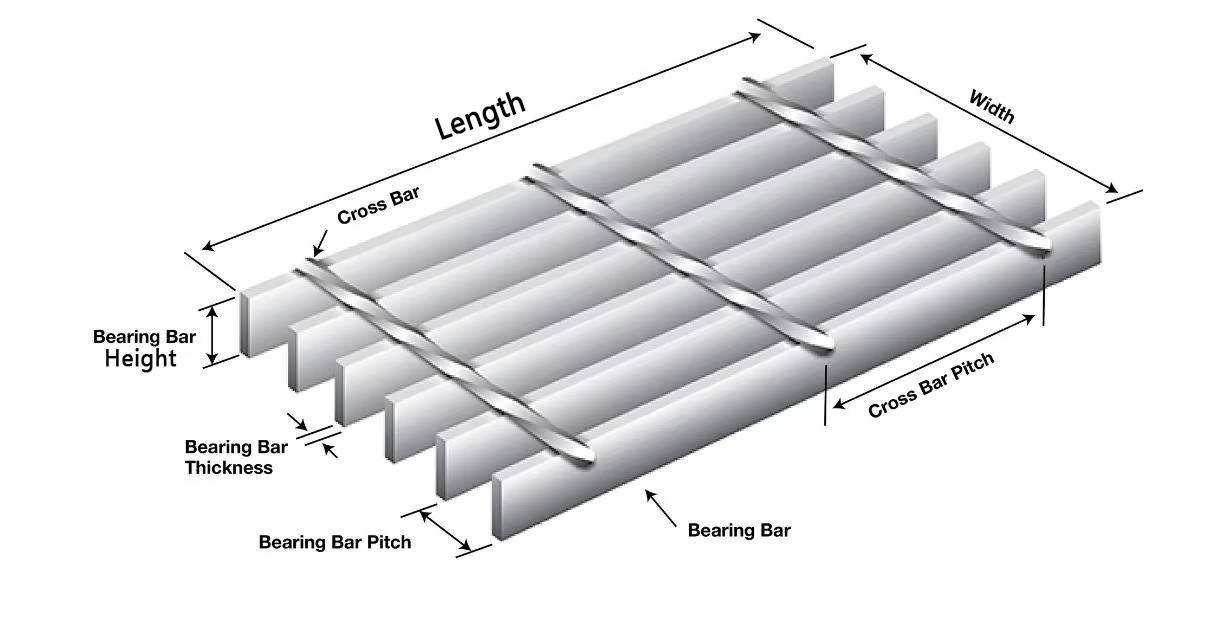

Steel grating, known for its robust design and superior spanning capabilities, offers exceptional strength and safety for various applications, including floor support and elevated walkways. Its versatility extends to a wide range of construction uses such as ceilings, interior decoration, platform aisles, ventilation windows, wells, and advertising plaques.

This type of grating is particularly valued for its high load-bearing capacity, anti-slip surface, and corrosion resistance, making it suitable for both industrial and architectural applications. Its open-grid structure also ensures efficient ventilation and drainage.

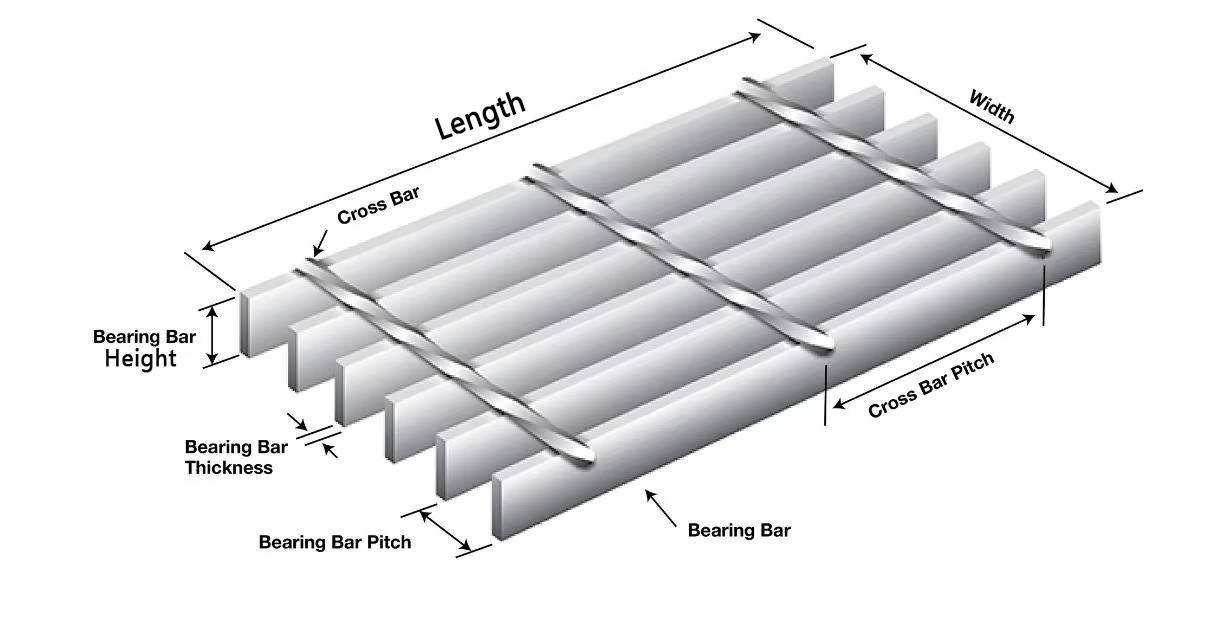

Specification Stainless Steel Grating

Types of Stainless Steel Grating

201 Material:

Contains manganese, has poor corrosion resistance, relatively low price, generally not recommended for use in corrosive environments.

304 material:

with average corrosion resistance, it is the most commonly used and recommended for use.

304L material:

Low carbon version, with similar corrosion resistance to 304, but better welding performance.

316 material:

It has strong corrosion resistance and is relatively expensive. Adding molybdenum element gives it a special structure that is resistant to corrosion.

316L material:

The low-carbon version of 316 has better welding performance.

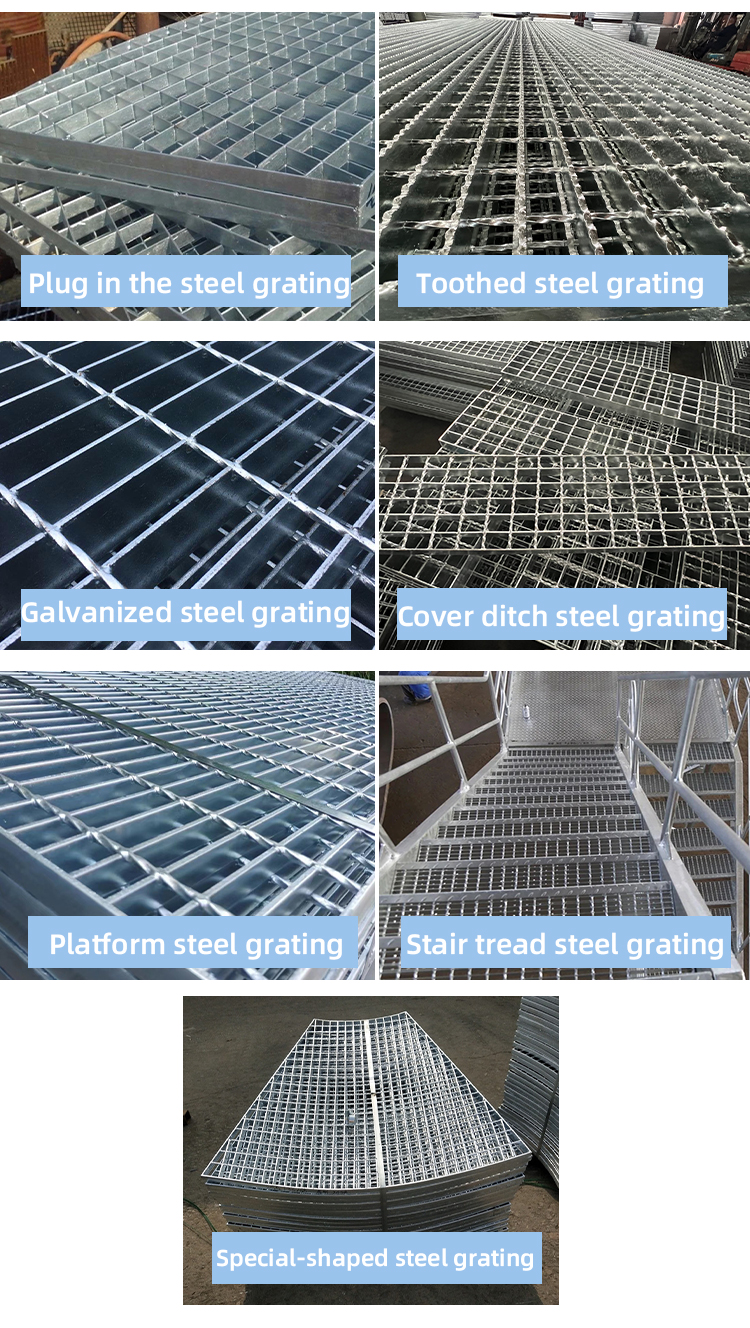

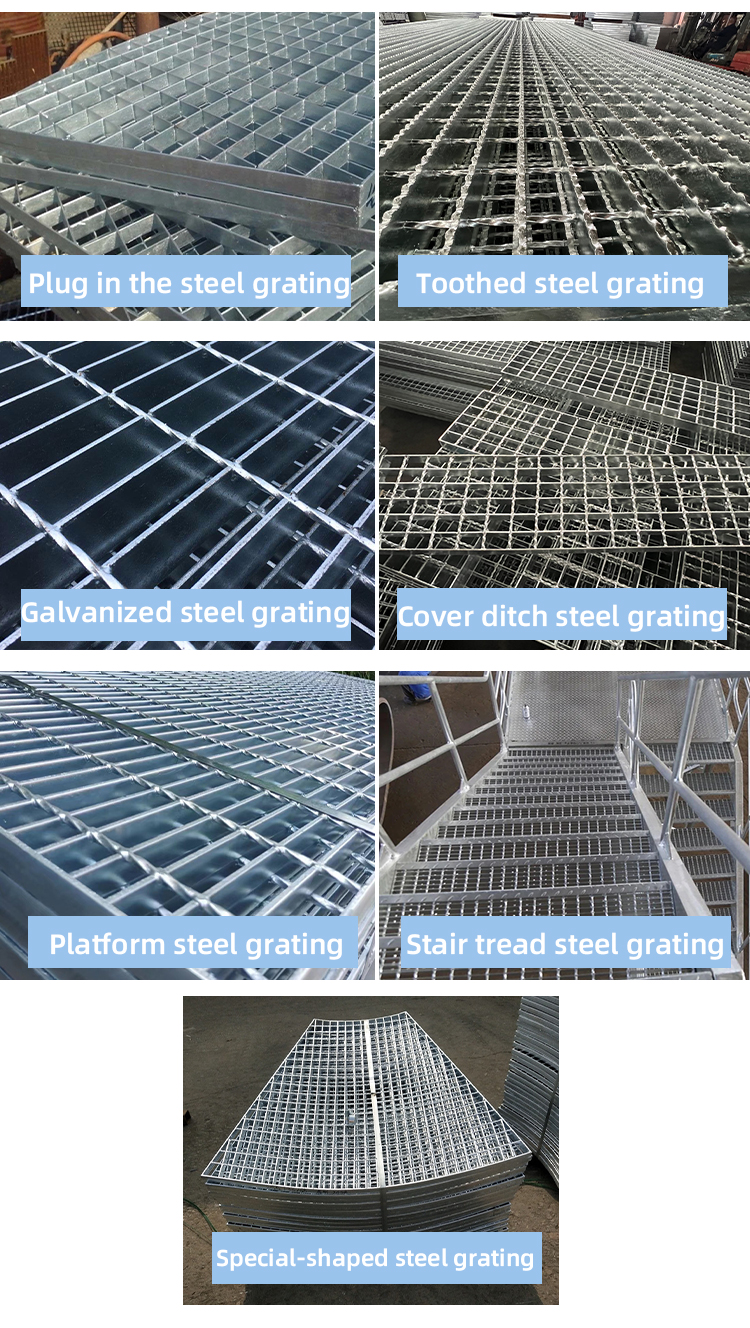

Kinds Of Steel Grating

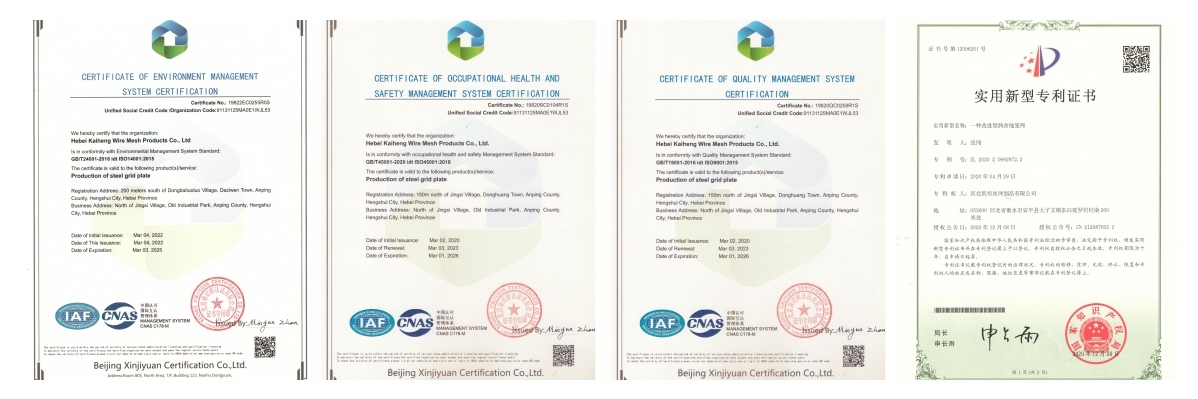

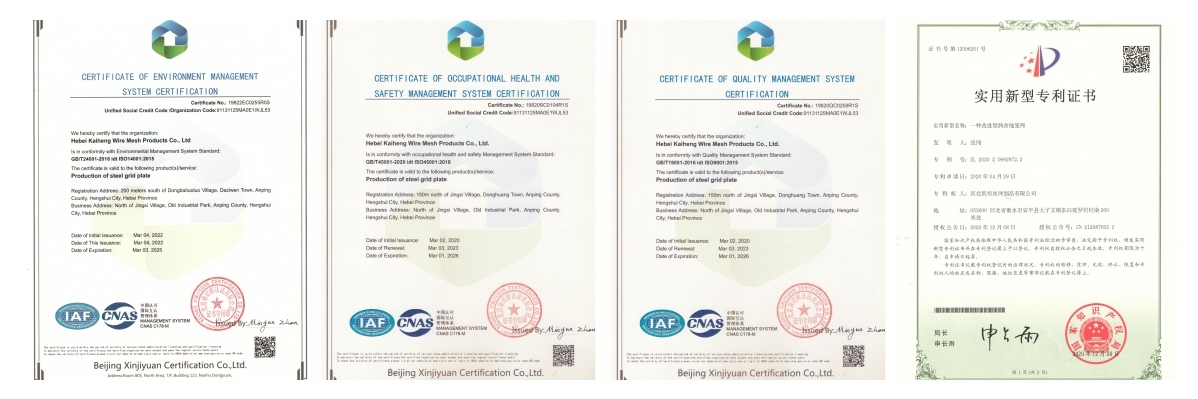

OUR CERTIFICATE

Our Factory Production

Hebei Kaiheng Wire Mesh Products Co. Ltd. is a leading manufacturer of steel grating platesproducing over 3000 plates daily and holding multiple quality certifications, focusing on industriessuch as petrochemical and hydropower.

Our Packaging And Transportation

1. International standard logistics packaging and transportation.

2. If customers have needs, we can customize special LOGO

3. Shanghai, Tianjin, Qingdao, Ningbo ports, you can specify other ports according to your needs.

Our After-sale Service

Provide a one-year product warranty to protect customer interests and ensure their peace of mind during use.

Sample service

Customized services

Quality assurance

Global coverage

ABOUT US

We are China sheet metal fabricator specializing in laser cutting, CNC bending, welding, polishing,powder coating and assembling with 20+ years custom- made sheet metal fabricationexperience, support OEM/ ODM, provide one- stop custom sheet metal fabrication services

We specialize in on-demand sheet metal fabrication and technical support, catering to a diverse range of industries. Our services are trusted by over 2000 customers worldwide, who benefit from our flexible manufacturing capabilities and receive highly cost-effective solutions for custom metal parts.