Steel Grating: The Guardian of Platform Safety And Efficiency

In many industrial production, construction, and warehousing logistics scenarios, platforms are an indispensable and important component. Steel grating, with its excellent performance and wide application advantages, has become the preferred material for platform construction, providing solid guarantees for the safe and efficient operation of various platforms.

1、 Characteristics of steel grating

Steel grating is a new type of material made by arranging load flat steel and horizontal bars at a certain distance in latitude and longitude, and using pressure welding technology. Its surface has a unique grid like structure, which endows the steel grating with many significant characteristics.

(1) High strength and high load-bearing capacity

The steel grating is made of high-quality steel and can withstand large loads through precise calculation and design. Whether it's the frequent movement of heavy machinery or the concentrated stacking of large amounts of goods, steel grating can easily handle it, ensuring the stability and safety of the platform. For example, on the shelf platform of a large logistics warehouse, steel grating can carry several tons of goods and is not easily deformed after long-term use, providing reliable support for the storage and handling of goods.

(2) Good ventilation, drainage, and lighting performance

The grid like structure of steel grating allows air, light, and liquid to flow freely. In some places that require good ventilation, such as chemical workshop platforms, steel grating can effectively discharge harmful gases, ensuring air circulation and freshness; In areas with heavy rainfall, steel grating platforms can quickly drain water, avoiding damage to the platform and equipment caused by accumulated water; At the same time, its transparency also saves lighting costs for indoor platforms and improves the comfort of the working environment.

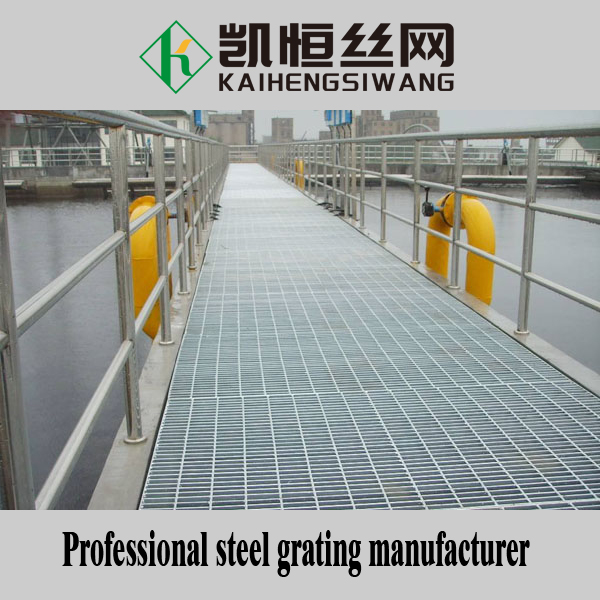

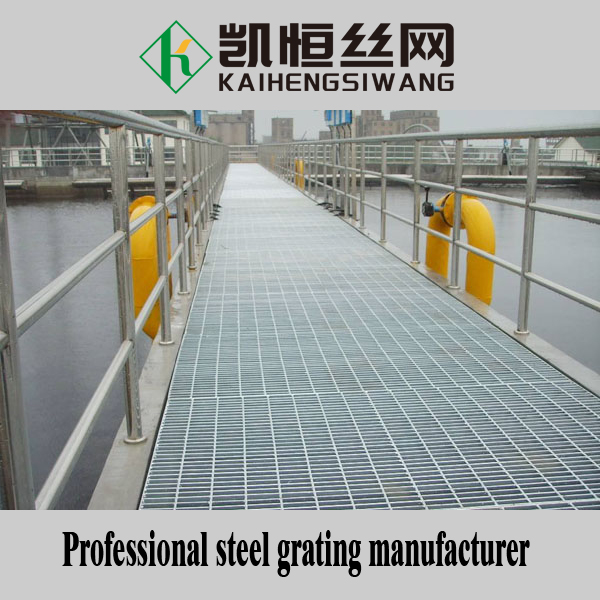

(3) Excellent anti slip performance

The surface of steel grating is usually treated with special methods such as hot-dip galvanizing, painting, etc., which not only increases its corrosion resistance, but also endows it with good anti slip performance. Even in damp and greasy environments, workers can maintain stability while walking on the steel grating, greatly reducing the risk of slipping and falling, providing strong protection for the personal safety of platform operators.

(4) Easy installation and maintenance

The size and shape of the steel grating can be customized according to the actual needs of the platform, and the installation process is simple and fast. By using bolt fixation or welding, the steel grating can be quickly and firmly connected to the platform frame. Moreover, the maintenance cost of steel grating is relatively low, and only regular cleaning and inspection are needed to maintain its good use condition, extend its service life, and save a lot of maintenance time and cost for enterprises.

2、 Application of Steel Grating in Different Platform Scenarios

(1) Industrial production platform

In industrial production fields such as mechanical manufacturing and electronic processing, steel grating platforms are widely used in production workshops, equipment maintenance platforms, and other areas. For example, on the equipment operation platform in the machining workshop, steel grating provides workers with a stable standing and operating space, and its ventilation performance helps to discharge metal shavings and coolant generated during the machining process, keeping the working environment clean. In the equipment maintenance platform, the high strength and anti slip characteristics of steel grating enable maintenance personnel to safely inspect and maintain large equipment, improve production efficiency, and ensure the normal operation of equipment.

(2) Construction Platform

The construction site environment is complex and there are many safety hazards. The application of steel grating in construction platforms provides a safe and reliable working environment for construction personnel. On the scaffold platform, the steel grating can withstand the weight of construction personnel and building materials, preventing personnel from falling due to stepping on it. Its good ventilation and drainage performance helps to discharge rainwater and construction wastewater, keep the scaffold platform dry, and reduce the probability of slip accidents. In addition, the installation and disassembly of steel grating are convenient, and the layout of the platform can be flexibly adjusted according to the construction progress, which improves the flexibility and efficiency of construction.

(3) Warehouse and logistics platform

The warehousing and logistics industry has high requirements for platforms, which need to have sufficient carrying capacity, good ventilation and drainage performance, and the characteristics of easy cargo handling. The steel grating shelving platform perfectly meets these needs. In logistics warehouses, steel grating shelving platforms can carry a large amount of goods, and the stacking and handling of goods are more convenient. Its ventilation performance is conducive to keeping the goods dry and preventing them from getting damp and deteriorating. At the same time, the grid like structure of the steel grating also facilitates the observation of the storage status of goods by the staff, improving the efficiency of warehouse management. On the loading and unloading platform of the logistics distribution center, the steel grating can withstand frequent crushing by heavy vehicles, ensuring smooth loading and unloading of goods and improving the efficiency and safety of logistics distribution.

(4) Ocean platform

The marine environment is harsh, requiring extremely high corrosion resistance and stability of platform materials. The steel grating undergoes special anti-corrosion treatment, such as hot-dip galvanizing, painting, etc., which can effectively resist the erosion of corrosive substances such as seawater and salt spray, extending the service life of the platform. Steel grating platforms provide a safe and stable working environment for workers in offshore oil drilling platforms, offshore wind power platforms, and other places. Its good ventilation and drainage performance helps to discharge seawater and rainwater, keeping the platform dry. In addition, the anti slip performance of steel grating is particularly important in wet and slippery marine environments, which can effectively prevent workers from slipping and getting injured, ensuring the safety of marine operations.